Views: 0 Author: Site Editor Publish Time: 2026-02-13 Origin: Site

Did you know most gutter failures start at the hanger? A weak support can cause sagging and leaks.

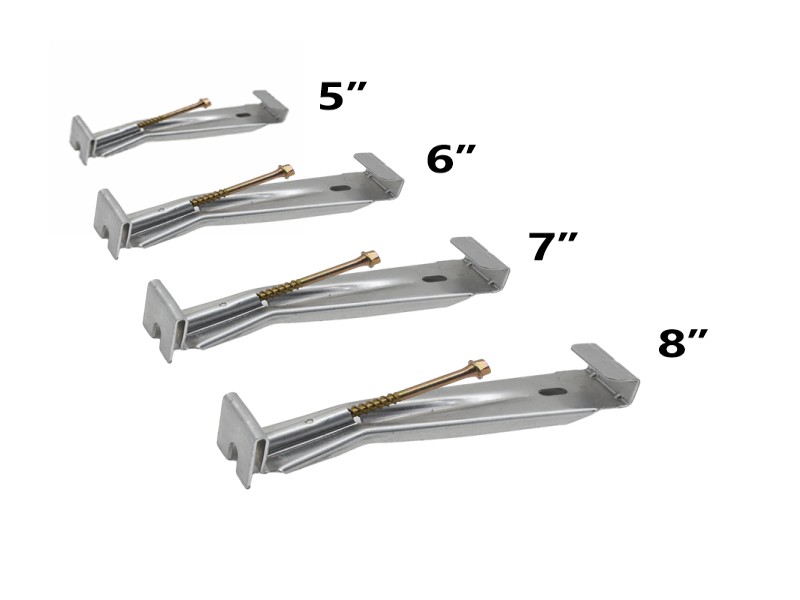

A strong Gutter Hanger keeps K-style aluminum gutters steady. Screw-and-clip designs are now widely used.

In this article, you will learn how it works. You will also discover installation tips and key benefits.

A hidden Gutter Hanger with a screw-and-clip design is engineered to support K-style aluminum gutters from inside the channel rather than from the exterior edge. Unlike older spike-and-ferrule systems that penetrate the gutter face, this design distributes structural load through internal contact points and anchors directly into the fascia board. The result is a cleaner exterior appearance combined with improved mechanical stability under rainfall, snow accumulation, and seasonal temperature changes. Understanding how each part of the hanger engages with the gutter profile is essential for proper installation and long-term performance.

The clip portion of the hanger is designed to hook securely beneath the rolled front lip of a K-style gutter. This rolled edge is not only decorative but also structural, providing a reinforced contour that resists bending. When the clip locks into place, it prevents outward separation and helps maintain the gutter’s horizontal alignment during heavy water flow. Because the connection occurs inside the channel, it preserves the smooth architectural line visible from the ground while still providing a firm mechanical grip.

Once engaged at the front lip, the hanger’s body extends toward the rear wall of the gutter, creating multiple internal contact points. These contact areas stabilize the gutter along its back wall and distribute pressure evenly instead of concentrating it at a single fastener point. This internal bracing effect reduces mid-span deflection and helps the gutter maintain consistent pitch across longer runs. The more evenly the load is distributed, the less likely the gutter is to twist or sag between supports.

From a structural perspective, the hanger functions as a load-transfer bridge. Water weight, debris accumulation, and ice buildup create downward force inside the gutter channel. Instead of allowing that force to distort the aluminum body, the hanger channels it backward into the fascia board through its rigid frame. The following table summarizes how each component contributes to structural stability:

Component | Primary Function | Structural Impact |

Rolled Front Lip | Engagement point for clip | Prevents outward spreading |

Internal Support Arm | Spans front to back wall | Reduces mid-span bending |

Back Wall Contact | Stabilizes rear alignment | Maintains consistent pitch |

Fascia Fastening Point | Transfers load to structure | Secures system under weight |

Together, these elements create a balanced internal support system that works with the K-style profile rather than against it.

While the clip secures the hanger to the gutter body, the screw is what anchors the entire assembly to the building structure. Proper screw placement requires attention to both angle and depth. Ideally, the screw should penetrate the fascia board at a perpendicular or slightly upward angle to maximize pull-out resistance. Driving the screw too shallow reduces holding strength, while over-tightening can distort the aluminum channel or strip the wood fibers inside the fascia.

Screw anchoring offers mechanical advantages over traditional spike systems. A threaded fastener grips the fascia fibers and resists gradual loosening caused by temperature expansion and contraction. Aluminum gutters expand in heat and contract in cold weather; a screw maintains compression against the hanger bracket, helping preserve alignment over multiple seasonal cycles. This continuous pressure reduces movement at joints and decreases the likelihood of future sagging between supports.

Material compatibility is also critical in aluminum gutter systems. Fasteners must resist corrosion while avoiding galvanic reactions between dissimilar metals. The table below outlines common fastening materials and their suitability for aluminum installations:

Fastener Material | Corrosion Resistance | Compatibility with Aluminum | Typical Use Case |

Zinc-Coated Steel | Moderate | Generally acceptable | Standard residential installs |

Stainless Steel | High | Excellent | Coastal or high-moisture areas |

Plain Carbon Steel | Low | Not recommended | Short-term or temporary use |

Selecting the correct screw type ensures that the hanger remains secure over time without compromising the integrity of the aluminum gutter. When installed correctly—with proper clip engagement and secure fascia anchoring—the hidden Gutter Hanger forms a structurally integrated support system capable of maintaining both alignment and drainage efficiency for years.

Installing a K-style aluminum Gutter Hanger system is not just about fastening brackets at regular intervals. The structural performance of the entire drainage system depends on thoughtful layout planning, correct pitch establishment, and precise spacing. Each of these factors works together: layout ensures alignment, pitch ensures drainage efficiency, and spacing ensures structural stability. When properly executed, the result is a gutter run that maintains both visual consistency and long-term load resistance under varying weather conditions.

Before a single hanger is installed, the entire gutter path should be mapped out from one end of the roofline to the other. This stage determines not only the total material length required but also where downspouts will be placed for optimal water discharge. Measuring the roofline carefully prevents mid-run adjustments that could disrupt alignment or cause uneven spacing between hangers. Downspout placement should consider foundation drainage, landscaping, and structural corners to ensure efficient water diversion away from the building envelope.

Equally important is evaluating the fascia board before fastening any Gutter Hanger. The fascia must be straight, structurally sound, and free from rot or warping. Fastening into weakened wood reduces pull-out resistance and can compromise long-term stability. If inconsistencies exist, they should be corrected prior to installation, as hangers follow the fascia line and cannot compensate for structural irregularities.

To maintain visual consistency, installers typically mark reference lines along the fascia board. A chalk line provides a clear guide for hanger placement and ensures that the finished gutter run appears straight when viewed from ground level. Even slight deviations become noticeable along long horizontal rooflines, so establishing a visual guide before fastening improves both structural accuracy and aesthetic outcome.

Pre-Installation Checklist:

● Confirm total roofline measurement

● Identify and mark downspout exit points

● Inspect fascia for alignment and integrity

● Snap reference lines for straight installation

A K-style aluminum gutter must maintain a slight downward slope toward the downspout to prevent standing water. The pitch does not need to be visually obvious; in fact, excessive slope can appear uneven. A subtle gradient allows gravity to move water efficiently while preserving a clean exterior line. Establishing pitch before fastening each Gutter Hanger ensures consistent water flow throughout the run.

Using a chalk line or laser level helps maintain uniform slope from the highest point to the outlet. Rather than adjusting each hanger individually, installers establish the high and low reference points first, then align intermediate hangers accordingly. This systematic approach reduces cumulative error and ensures consistent gradient across long sections.

The table below summarizes recommended pitch guidelines for typical residential installations:

Gutter Run Length | Recommended Slope | Drainage Outcome |

Up to 20 ft | Subtle downward pitch | Reliable runoff with minimal visual change |

20–40 ft | Slightly increased gradient | Prevents pooling in mid-span areas |

Over 40 ft | Multi-outlet or sectional slope | Maintains efficient water transfer |

Maintaining proper pitch minimizes overflow risk during heavy rainfall and reduces debris accumulation caused by stagnant water. The goal is functional drainage without noticeable tilt from the street view.

Spacing directly affects the structural integrity of a Gutter Hanger system. In standard residential environments, hangers are typically installed at consistent intervals that provide adequate support without unnecessary hardware density. Uniform spacing ensures even load distribution and reduces localized stress points along the aluminum channel.

In regions prone to heavy snowfall or ice accumulation, tighter spacing becomes essential. Snow load significantly increases downward force within the gutter channel, and closer hanger placement reduces mid-span deflection. Adjusting spacing based on climate conditions enhances long-term structural reliability without altering the basic installation method.

Special attention should also be given to high-stress areas, such as corners, seams, and downspout outlets. These locations experience increased mechanical movement and water concentration. Reinforcing these zones with additional support minimizes joint separation and preserves alignment over time.

Installation Area | Recommended Support Strategy | Purpose |

Straight runs | Standard interval spacing | Even weight distribution |

Snow-prone regions | Reduced spacing intervals | Increased load resistance |

Corners and seams | Additional hanger nearby | Structural reinforcement |

Near downspouts | Extra support before outlet | Prevent sag at drainage point |

Proper spacing transforms the hanger system from a simple attachment method into a distributed structural framework. When layout, pitch, and spacing are aligned correctly, the aluminum K-style gutter performs efficiently under seasonal stress while maintaining a consistent exterior appearance.

Aluminum K-style Gutter Hanger systems are designed not merely as attachment hardware, but as structural components that influence the durability, alignment, and long-term performance of the entire gutter assembly. When paired with a screw-and-clip mechanism, these hangers provide internal reinforcement that supports the gutter channel under rain load, debris accumulation, and seasonal expansion. Their benefits extend beyond strength alone—they contribute to stability, appearance, and ease of maintenance over time.

Aluminum offers inherent corrosion resistance, making it well-suited for exterior drainage systems exposed to rain, humidity, and fluctuating temperatures. Unlike untreated steel components that may oxidize, properly coated or stainless fasteners used with aluminum hangers reduce the risk of long-term deterioration. This corrosion resistance helps maintain fastening integrity and ensures that the hanger continues to perform under repeated wet-dry cycles.

Temperature cycling introduces expansion and contraction within the gutter channel. During hot seasons, aluminum slightly expands; during colder periods, it contracts. A screw-based Gutter Hanger accommodates these movements more effectively than spike systems because threaded fasteners maintain continuous compression against the fascia board. Spikes, by contrast, rely on friction and can gradually loosen as wood fibers compress or shift over time.

Because the screw penetrates the fascia with a threaded connection, it distributes holding force along its shaft. This improves resistance to pull-out and reduces the likelihood of seasonal shifting, particularly in climates with significant weather variation.

Even distribution of Gutter Hanger placement directly affects sag prevention. When hangers are spaced consistently, downward forces from water weight and debris are shared across multiple support points rather than concentrated at isolated intervals. This reduces mid-span deflection and maintains the gutter’s original pitch. Over time, consistent support prevents the gradual bowing often observed in under-supported systems.

Spacing strategy and fascia anchoring also influence long-run alignment. Secure anchoring into structurally sound fascia boards ensures that the gutter remains flush against the roofline. If anchoring is uneven or inconsistent, slight shifts can accumulate along the run, eventually altering slope and drainage efficiency. Stability over time therefore depends on both proper initial spacing and reliable fastening.

In real-world drainage performance, “stable over time” typically means:

● No visible sagging between hangers after heavy rainfall

● Consistent water flow without pooling

● No separation at seams due to misalignment

● Minimal need for post-installation adjustments

When these indicators remain consistent across multiple seasons, the hanger system is functioning as intended.

A hidden aluminum Gutter Hanger system preserves the architectural lines of a K-style gutter profile. Because the bracket is positioned inside the channel, no external hardware interrupts the decorative front edge. This creates a continuous exterior appearance that blends with both modern and traditional home designs. The absence of visible spikes or brackets also contributes to a more finished aesthetic when viewed from ground level.

Compared to external brackets, internal hangers reduce visible hardware clutter. This streamlined look not only enhances curb appeal but also minimizes points where debris can snag or accumulate. Fewer exposed components mean less opportunity for corrosion staining or surface wear along the gutter face.

From a maintenance standpoint, screw-based hangers offer practical advantages. If minor settling occurs over time, individual screws can be tightened without dismantling the entire system. Realignment adjustments are typically localized rather than structural. This ability to fine-tune support points extends the service life of the gutter run and reduces the likelihood of major corrective work.

Collectively, these benefits demonstrate that aluminum K-style Gutter Hanger systems are engineered not only for initial strength, but for sustained structural integrity, consistent drainage performance, and long-term visual continuity.

Even a high-quality aluminum Gutter Hanger system can underperform if installation fundamentals are overlooked. Most long-term issues—sagging, leakage, misalignment, or pooling—can be traced back to avoidable setup errors rather than product defects. Because K-style gutters rely on distributed internal support and precise slope, small inaccuracies during installation often compound over time. Understanding these common mistakes helps prevent structural inefficiencies and reduces the need for premature adjustments or repairs.

One of the most frequent mistakes is inconsistent hanger spacing. When the distance between hangers varies significantly along a gutter run, weight is unevenly distributed. Sections with wider gaps bear greater load during heavy rainfall or snow accumulation, increasing the risk of mid-span deflection. Over time, this imbalance can distort the gutter profile and alter drainage pitch. Maintaining consistent spacing ensures that structural forces are shared across all attachment points rather than concentrated in isolated areas.

Another critical issue is fastening into compromised fascia boards. If the wood behind the gutter is soft, rotted, or uneven, even a properly installed screw-based hanger cannot achieve secure anchorage. The fascia must provide firm resistance to pull-out forces; otherwise, screws may gradually loosen despite correct spacing. Before installation, fascia integrity should be evaluated and repaired if necessary to ensure reliable long-term support.

Installation Factor | Common Error | Structural Consequence |

Hanger Spacing | Irregular intervals | Uneven load distribution |

Fascia Condition | Soft or deteriorated wood | Reduced pull-out resistance |

Fastener Placement | Misaligned screw angle | Weakened anchoring strength |

Ensuring uniform spacing and fastening into structurally sound fascia boards creates the foundation for stable gutter performance.

Incorrect pitch is another frequent cause of performance issues. If the gutter slope is too flat, water may pool in sections instead of flowing toward the downspout. Conversely, excessive pitch can create visible tilt along the roofline and strain seam connections. A subtle and consistent gradient is necessary to balance effective drainage with aesthetic alignment.

Overtightening screws represents a less obvious but equally significant mistake. When screws are driven with excessive force, the aluminum channel can deform around the hanger bracket. This deformation may create small depressions where water collects or weaken the structural profile of the gutter wall. Because aluminum is relatively lightweight, controlled fastening pressure is essential to maintain its original shape and performance.

Installers should monitor the following warning signs during installation:

● Visible channel distortion near hanger locations

● Sections where water does not flow evenly during testing

● Noticeable misalignment along the roof edge

Careful control of pitch and fastening tension helps preserve both drainage efficiency and structural integrity.

Skipping post-installation water testing is a preventable oversight that can lead to unresolved drainage issues. Even when spacing and pitch appear correct visually, small alignment deviations may only become evident once water flows through the system. Testing allows installers to confirm consistent runoff toward downspouts and detect minor pooling or seam leaks before they develop into larger problems.

Leak checks at joints and outlet connections are particularly important. While Gutter Hanger placement affects structural support, water tightness depends on properly sealed seams and stable alignment. A brief water test provides immediate feedback and allows adjustments to hanger positioning or pitch before the system is fully relied upon during heavy rainfall.

In practice, a well-installed aluminum K-style Gutter Hanger system should demonstrate uniform alignment, consistent slope, and uninterrupted water flow. Avoiding these common installation mistakes significantly improves long-term performance and reduces the likelihood of sagging, overflow, or structural adjustment in the future.

A Gutter Hanger is not a small part. It supports the whole gutter system. Good layout, pitch, and spacing matter. They protect long-term drainage flow.

Aluminum screw-and-clip designs add strength. They improve stability and clean appearance. Products from Hangzhou Wonder Hardware Manufacturing Co., Ltd. offer durable support and reliable performance.

A: A Gutter Hanger supports the gutter channel, maintains pitch, and transfers load to the fascia board.

A: Standard Gutter Hanger spacing is 18–24 inches, with closer intervals in snow-prone regions.

A: A screw-based Gutter Hanger provides stronger pull-out resistance and better long-term alignment.

A: Proper slope ensures each Gutter Hanger maintains drainage efficiency and prevents standing water.